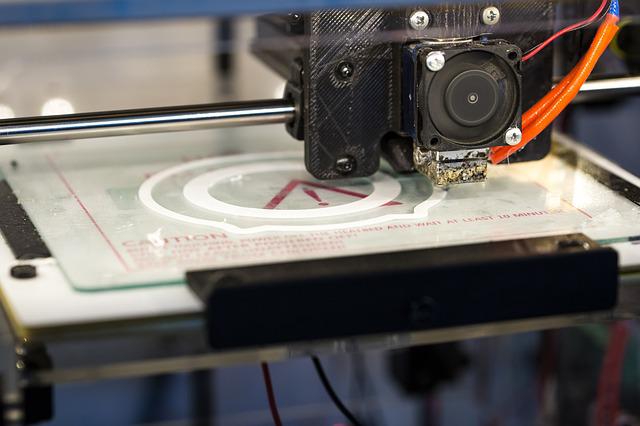

How to utilize the 3D printing to create a prototype

Models are used to test things. A model is created once the hidden plans and judgments have been made. Associations use them to test the certified convenience and sensibility of their things. A model can seem anticipated blemishes and can show expecting a thing will truly work.

Models can be refined but again anticipated various events – consequently the cooperation ought to be shrewd and powerful. 3D printing setup can without a doubt additionally foster viability and change the model creation process into a streamlined action.

We have recorded six explicit nuances underneath how 3D printing can be used to make a model for your new thing plan:

1> Improve creation and Design Process

3D printing can truly additionally foster efficiency phenomenally. It can dispose of an enormous piece of the goals that the standard creation process presents. While making models using customary procedures, you really want to rely upon the social affair of parts. Moreover, you want to address individual parts and plan parts. 3D printing starts with 3D showing organizations and can convey models from one whole piece of material – parts needn’t bother with to be fixed together.

This, clearly, is effective, but it similarly suggests that makers can zero in on the authentic model and plan itself – they don’t have to worry about organizing the model or endeavoring to develop it. They can make different arrangements and play with new components and plan parts without adding a ton of opportunity to the whole show process.

2> Improve Efficiency during the Prototype Stage

It is by and large understood that standard gathering processes are not enormously useful. It is surveyed that ordinary use for collecting processes is essentially 75%. This suggests that there is 25% or a more prominent measure of waited around lazily.

This 25% can achieve reduced creation and ultimately diminished pay and arrangements. Suitably, one out of four cycles are not adding to the genuine creation process, or are being under-utilized.

This is every now and again the case since master cycles are used that need versatility and adaptability. Pass on anticipating and imbuement framing, for example, require master device and cycles to work. But 3D printing is explicit, it is also adaptable. A 3D printer isn’t obliged to one kind of thing or one material – a single 3D printer could be used to cultivate 15 absolutely different models for example.

Generously Visit https://3dsculplab.xyz/Blog/post/3D-Printed-Hand-sanitizer-bottle-

By using 3D printing to cultivate models, you can immensely additionally foster your viability. You can streamline the model progression process which can finally additionally create delivering times and augmentation your general outcome.

3> Reduce Wastage of Materials

All through the world, associations are attempting to be useful and decrease their wastage. Acting constantly and innocuous to the environment is a significant notwithstanding and can help with giving associations a high ground. It is also a phenomenal technique for saving costs and further foster pay. 3D printing can truly help with decreasing wastage of work, time and materials.

Did you had in any event some thought that the benchmark rate for collecting wastage is 21%? It is acknowledged that 3D printing can truly lessen this to under 10%. In addition, while using 3D printing to thing models, you can basically reduce your carbon impression.

How is it that this could be achieved? Without skipping a beat, the 3D printing process is less energy serious and requires less capacity to work. Moreover, you use less materials to create your test plans. Yet again thirdly, plans can without a very remarkable stretch be changed and made using the 3D planning programming, which can reduce work costs.

4>Provide Manufacturing as a Viable Service

Manufacturing as a help is transforming into a plausible business action. You have unquestionably referred to about the term Software as a Service (SaaS) – MaaS is presumably going to follow and become well known. This is transforming into an affirmation because of 3D printing. Associations are drifting away from single thing creation and setting up their business to oversee various plans and clients.

Associations can basically use 3D printing to upgrade their thing stock and appeal to significantly greater market. They can make a lot of 3D models and find headway in considerably less time

3D printing is verifiably an interesting street to research. As development improve, we can guess that the utilization of this cycle should increase. In addition, we ought to see more confounded plans being made as programming, material cycles, and the genuine printers are made.

Verifiably, for the development of models, 3D printing can generally change this whole ineraction. It can additionally foster capability. Also, it can reduce costs and creation times. Associations can contribute less energy making models, and contribute extra time instead of refining and further fostering their authentic things and systems.

5> Improving Basic Design Mechanisms

Customary collecting and model progression had limits. Without skipping a beat, the customary cycle was separated into different stages. Besides, the genuine model was by and large made in a startling material in contrast with the genuine completed outcome. This inferred that inconsistencies much of the time arose and that the model was surely not a certifiable impression of the genuine thing.

3D printing can additionally foster the fundamental arrangement cycle and instruments. The model can be made in definitively a similar material as the end-product – this can, clearly, further foster precision.

Moreover, the certifiable arrangement process is streamlined – a high level string can be used at various stages which further creates connection. There is not a great explanation to make different models for each period of the communication – a fashioner can sufficiently design one model and take it through the different stages straight up to the genuine 3D printing process.